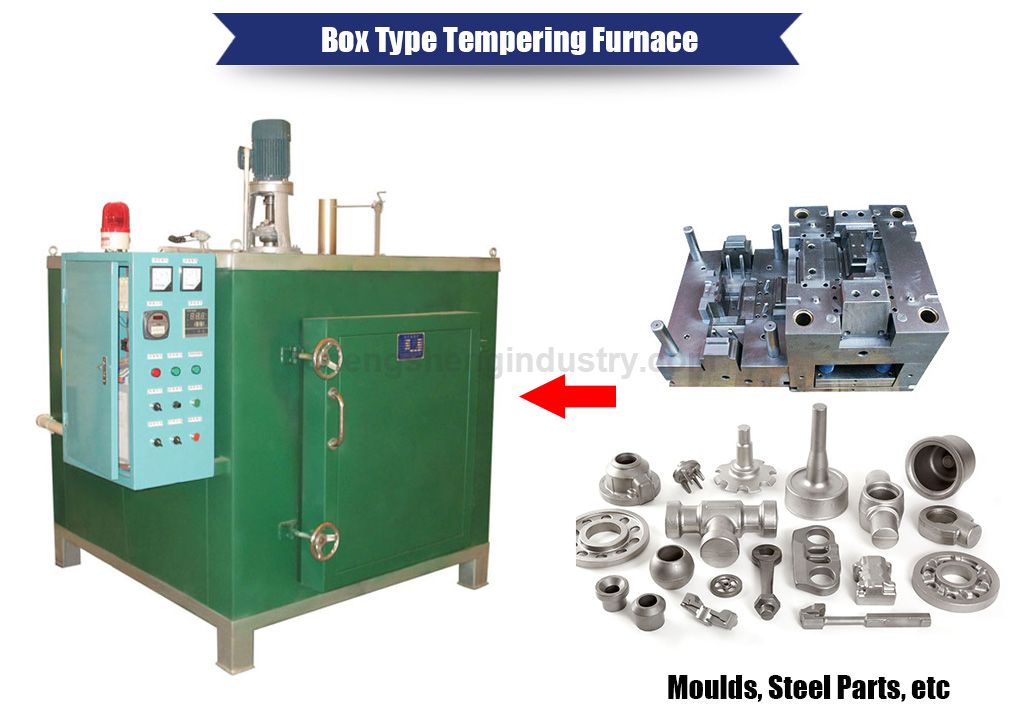

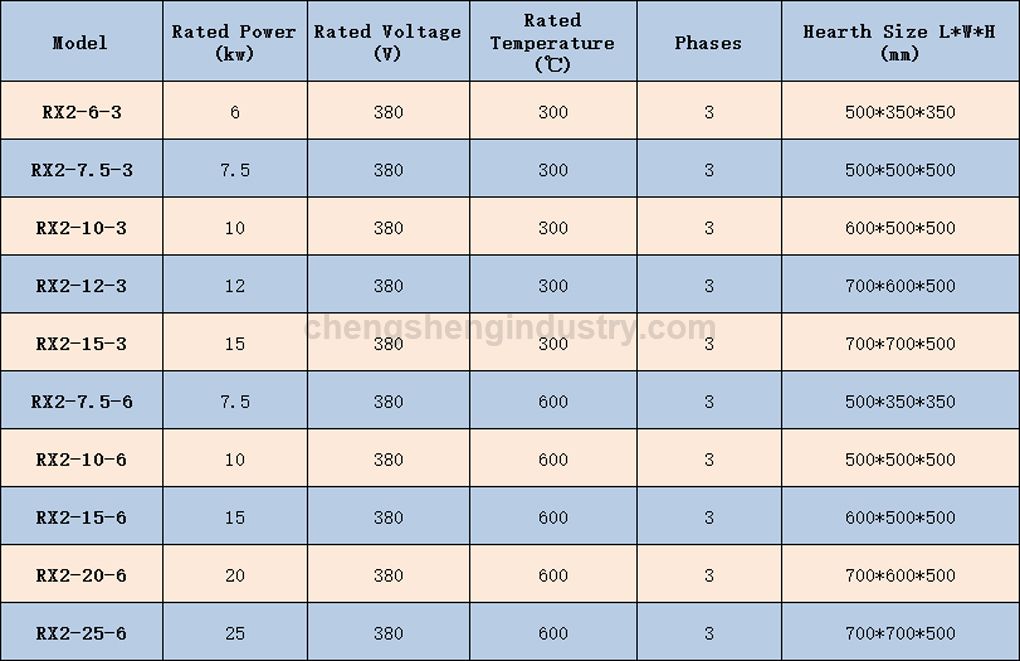

High Temperature Chamber Electric Resistance Furnace for Tempering

Tips:We have Professional R&D engineer, Customized furnaces as your required is welcome.

Brief Introduction:

For heating, aging and tempering of moulds and steel parts in petrochemical industry, medical service and laboratory.

Characteristics:

1. Adopt mixed furnace lining of ultra-light refractory bricks (0.6/cubic meter) and ceramic fiber, greatly shortening starting heating time and extraordinarily saving energy up to 20%-30%.

2. Specially-designed furnace door and roller sealing, and built-in heating wire ensure excellent furnace door sealing and uniform furnace temperature.

3. Double-thermocouple control: one thermocouple is for testing furnace temperature, and the other one is for over-heat protection.

4. The furnace is equipped with interlock protection device, which can prevent Failure and accident due to misoperation.

5. Adopt intelligent digital temperature-control system, which feature clear reading, conveniently adjusted, high temperature control precision, easy structure, safe and reliable.

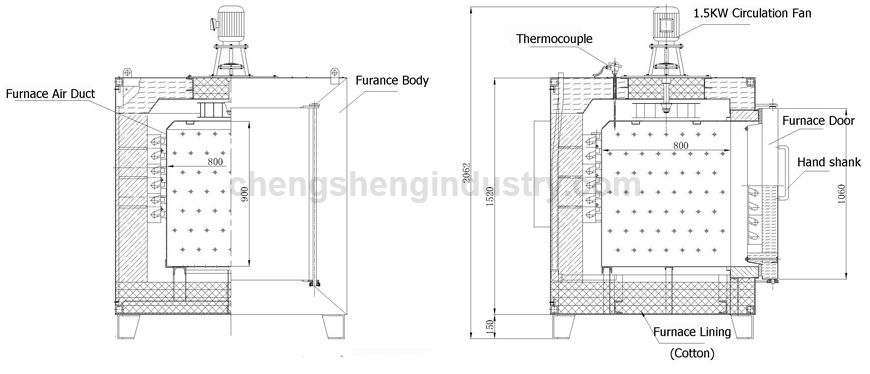

Box Type Tempering Furnace Drawing:

Moulds and steel parts, etc

Application