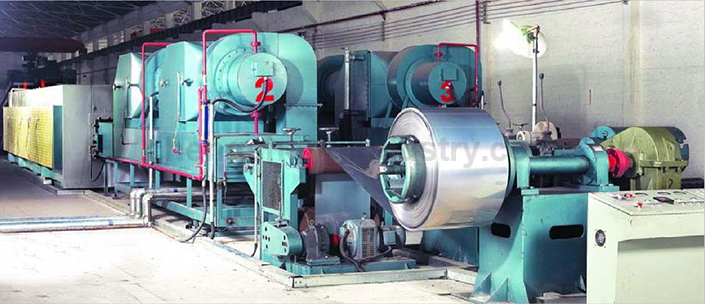

Cold rolled stainless steel strip continuous bright annealing furnace production line

Tips:We have Professional R&D engineer, Customized furnaces as your required is welcome.

Brief Introduction:

ZLG series cold rolled stainless steel strip continuous bright annealing furnace production line is a continuous working electric furnace, is a special equipment for cold rolled stainless steel strip continuous bright annealing. The furnace design is novel, reasonable structure, energy saving and high thermal efficiency, stable production quality, safe and convenient use, simple operation and no industrial pollution.

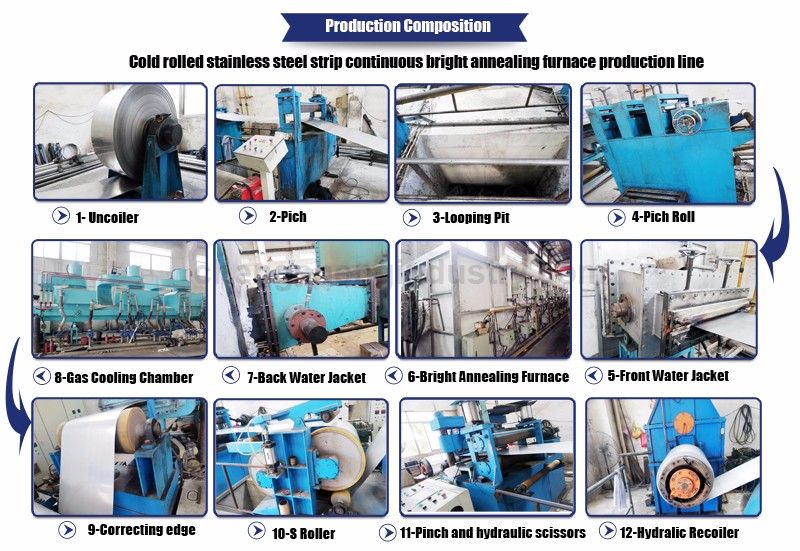

Furnace Composition:

The basic configuration of ZLG series cold rolled stainless steel belt continuous bright annealing furnace production line includes: Mechanical Uncoiler, Pinch, Looping Pit , Pinch Roll, Front- Water Jacket, Bright Annealing Furnace, Back-Water Jacket, Gas Cooling Chamber, Correct Edge, S roller, Pinch And Hydraulic Scissors, Hydraulic Recoiler, operating table, ammonia cracker and electrical control cabinet.

Advantage:

1)Steel belt conveying is stepless speed regulation, equipped with recoiler and uncoiler mechanism to ensure that steel belt recoiling does not occur running phenomenon.

2)Equipped with an ammonia decomposing device, the liquid ammonia is decomposed into (hydrogen 75%, nitrogen 25%) mixed gases into the furnace chamber to achieve the gas protection effect.

3)Ammonia decomposition gas cooling chamber and circulating heat exchange device can ensure that the material temperature of stainless steel belt comes down to the technological requirements when it comes out of the oven, and ensure that the surface of stainless steel belt after annealing is bright, no oxidation and no scratch.

6)Muffle pipe is made of imported high temperature resistant stainless steel by pressing and welding.

7)The heating element is made of high temperature heating material, which is distributed in the upper and lower heating area. It is very convenient to replace, which does not affect the production, and is safe and durable.

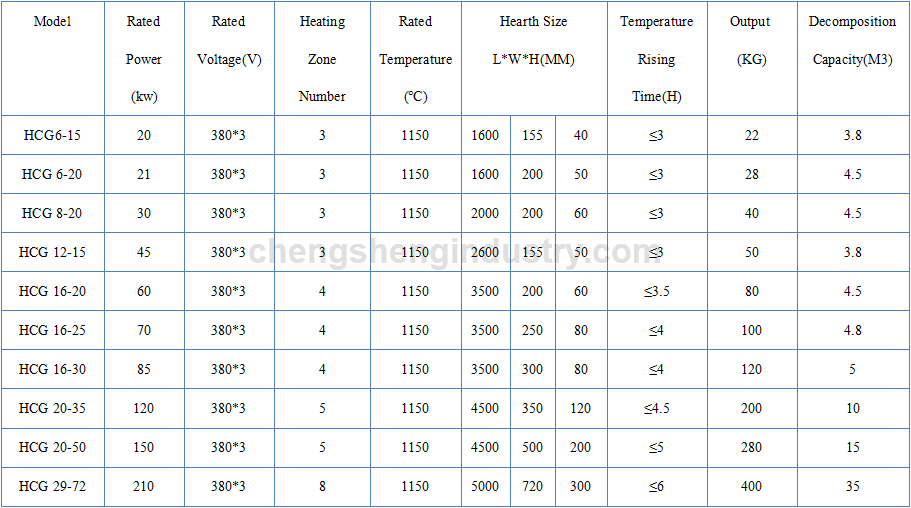

Technical Parameters

Applications

Mainly used for continuous bright quenching of Martensitic stainless steel,

bright annealing of austenitic stainless steel without oxidation under the high temperature.

Such as SUS420J2, 3Cr13, 410, 301, 304, 316, 3156L, 420, S315, 201, 202, etc..