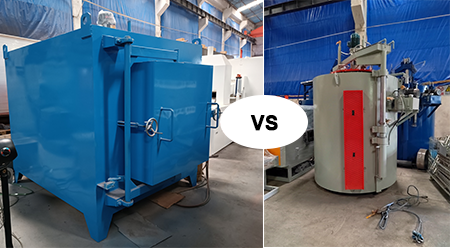

Comparison between Box-type Heat Treatment Furnace and Pit-type Heat Treatment Furnace

Feb. 17, 2025

Box-type Heat Treatment Furnace and Pit-type Heat Treatment Furnace exhibit significant differences in terms of structure, operating mode, applications, as well as advantages and disadvantages. Below is a detailed comparison of the two:

I. Structural Characteristics

Box-type Heat Treatment Furnace:

Furnace Structure: Enclosed rectangular or square furnace chamber.

Loading Method: Workpieces are typically placed horizontally inside the furnace chamber.

Pit-type Heat Treatment Furnace:

Furnace Structure: Cylindrical deep-well structure with the upper part serving as the furnace chamber and the lower part housing the heater or burner.

Loading Method: Workpieces can be suspended inside the furnace, making it particularly suitable for slender rods and long shafts.

II. Operating Mode

Box-type Heat Treatment Furnace:

Heating Method: Workpieces are heated through the heat generated by heaters or burners.

Temperature Control: Generally equipped with a temperature control system, but temperature uniformity may be affected by the shape and placement of workpieces.

Pit-type Heat Treatment Furnace:

Heating Method: Workpieces are heated through radiation and convection.

Temperature Control: Equipped with advanced temperature control systems capable of precise temperature control, which enhances the uniformity of heat treatment and product quality.

III. Applications

Box-type Heat Treatment Furnace:

Scope of Application: Suitable for small workpieces and small-batch heat treatment.

Industry Applications: Widely used in industries such as petrochemicals, power, education, coal, agriculture, animal husbandry, and pharmaceutical research.

Pit-type Heat Treatment Furnace:

Scope of Application: Suitable for slender rods, long shafts, and heat treatment processes requiring precise temperature control.

Industry Applications: Primarily used in industries such as steel, non-ferrous metals, machinery manufacturing, and automobiles.

IV. Advantages and Disadvantages

Box-type Heat Treatment Furnace:

Advantages:

Simple structure and easy operation.

Large loading capacity, suitable for heat treatment of small and medium-sized machine parts.

Relatively stable temperature control, though it may be affected by workpiece shape.

Disadvantages:

Horizontal placement of long rods or slender workpieces can lead to deformation.

Temperature uniformity may be inferior to pit-type furnaces.

Pit-type Heat Treatment Furnace:

Advantages:

Excellent temperature uniformity, enhancing the uniformity of heat treatment and product quality.

Suitable for heat treatment of slender rods and long shafts, reducing deformation.

Compact structure, small footprint, and convenient for factory layout.

Equipped with advanced temperature control systems for precise temperature control.

Disadvantages:

Relatively complex operation, requiring special cranes or overhead traveling cranes for loading.

For large workpieces, larger pit-type furnaces may be required to meet demands.

In summary, Box-type Heat Treatment Furnaces and Pit-type Heat Treatment Furnaces each have their unique advantages and applicable scopes. When selecting, comprehensive consideration should be given to the type and size of workpieces, heat treatment requirements, and the actual conditions of the factory.