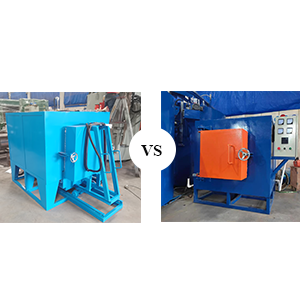

Comparison between Trolley Type Heat Treatment Furnace and Pit Type Heat Treatment Furnace

Mar. 24, 2025

Both the trolley type heat treatment furnace and the pit type furnace have their own characteristics in the field of heat treatment. Below is a detailed comparison of the two:

Trolley Type Heat Treatment Furnace | Pit Type Heat Treatment Furnace | |

Structural characteristics | The furnace bottom is equipped with a movable trolley, which enters and exits the furnace body through a traction mechanism. The furnace chamber is not divided into sections, and the workpieces are placed on the trolley for heat treatment. | The furnace body is a cylindrical deep-well structure, and the workpieces are vertically loaded into the furnace for heating by a dedicated crane. The furnace is typically installed below the workshop floor level, although some are also installed above ground. |

Application scenarios | It is applicable for the heat treatment of large steel ingots, billets, steel plates, as well as large castings, forgings, and welded components. It is commonly used in processes such as annealing, normalizing, and quenching. | It is suitable for the heat treatment of rod-type and long-shaft components, such as quenching, tempering, carburizing, etc. |

Operation mode | The trolley moves in and out of the furnace body to facilitate the loading and unloading of workpieces. It can operate continuously or intermittently, with flexible adjustments according to production requirements. | The workpiece is vertically loaded and unloaded using a crane, making the operation relatively simple. It belongs to a periodic operation furnace. |

Heating method | It can adopt fuel heating (such as gas or oil) or electric heating. Choose the appropriate heating method according to the process requirements. | It is typically heated using gas, fuel oil, or electricity. When heated by electricity, it is referred to as a pit type resistance furnace. |

Temperature control | The temperature range is wide and can be set according to specific process requirements. It is equipped with an advanced temperature control system to ensure temperature uniformity and stability. | The temperature control is precise, equipped with a ventilation device and air guide barrel to improve the uniformity of the temperature inside the furnace. |

Advantages and disadvantages | Advantages: Compact structure, flexible operation, suitable for heat treatment of large workpieces. Disadvantages: The workpiece may be unevenly heated during the heating process, and the furnace temperature may drop when loading and unloading materials. | Advantages: Suitable for long shaft-type parts, with good heating uniformity and easy operation. Disadvantages: Limited furnace chamber volume, not suitable for batch processing of large workpieces. |

Applicable materials | It is suitable for various metal materials including high-chromium and high-manganese steel castings, gray iron castings, ductile iron castings, rolling mills, steel balls, crusher hammers, wear-resistant liner plates, and more. | It is mainly used for the heat treatment of metal materials and mechanical parts such as alloy steel, high-speed steel, high-manganese steel, high-chromium steel, shafts, tubing, and more |

Summary:

The trolley type heat treatment furnace is suitable for the heat treatment of large workpieces, offering flexible operation, but the uniformity of heating may be somewhat affected.

The pit type furnace is applicable for the heat treatment of rod-like and long-shaft parts, providing good heating uniformity and simple operation, but with limited furnace chamber capacity.

When selecting, comprehensive consideration should be given to factors such as the size and shape of the workpieces, heat treatment process requirements, and production scale, in order to choose the most suitable heat treatment equipment.