Four common phenomena in heat treatment process

Jun. 22, 2024

1.Overheating

Overheating during heat treatment is most likely to cause the coarsening of austenite grains, which will reduce the mechanical properties of parts.

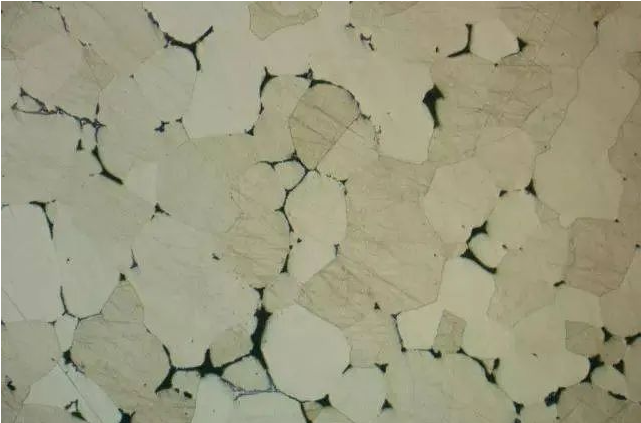

1) General overheating: Overheating is caused by excessively high heating temperature or too long holding time at high temperature, which causes the coarsening of austenite grains. Coarse austenite grains will reduce the strength and toughness of steel, increase the brittle transition temperature, and increase the tendency of deformation and cracking during quenching. The cause of overheating is the loss of control of the furnace temperature instrument or mixing (often caused by ignorance of the process). Overheated tissue can be re-austenitized to refine the grains under normal circumstances after annealing, normalizing or multiple high-temperature tempering.

2) Fracture inheritance: After reheating and quenching of steel with overheated tissue, although the austenite grains can be refined, coarse granular fractures sometimes still appear. There are many controversies about the theory of fracture inheritance. It is generally believed that the impurities such as MNS were dissolved into austenite and enriched at the grain interface due to the excessively high heating temperature. When cooling, these inclusions will precipitate along the grain interface and easily break along the coarse austenite grain boundary when impacted.

3) Inheritance of coarse structure: When steel parts with coarse martensite, bainite, and widmanstattenite structures are re-austenitized, they are slowly heated to the conventional quenching temperature, or even lower, and their austenite grains are still coarse. This phenomenon is called tissue inheritance. To eliminate the inheritance of coarse structure, intermediate annealing or multiple high-temperature tempering treatments can be used.

2.Overburning

If the heating temperature is too high, not only will the austenite grains become coarse, but also the grain boundaries will be partially oxidized or melted, resulting in the weakening of the grain boundaries, which is called overburning. The performance of the steel will be seriously deteriorated after overburning, and cracks will form during quenching. The overburned structure cannot be restored and can only be scrapped. Therefore, overburning should be avoided during work.

3. Decarburization and oxidation

When steel is heated, the carbon on the surface reacts with oxygen, hydrogen, carbon dioxide and water vapor in the medium (or atmosphere), reducing the surface carbon concentration, which is called decarburization. After quenching, the surface hardness, fatigue strength and wear resistance of decarburized steel are reduced, and residual tensile stress is formed on the surface, which is easy to form surface network cracks. When heated, the iron and alloy elements on the surface of the steel react with oxygen, carbon dioxide, water vapor in the medium (or atmosphere) to form an oxide film, which is called oxidation. After high-temperature (generally above 570 degrees) workpieces are oxidized, the dimensional accuracy and surface brightness deteriorate, and steel parts with poor hardenability of oxide films are prone to quenching soft spots. Measures to prevent oxidation and reduce decarburization include: coating the surface of the workpiece, sealing and heating with stainless steel foil packaging, heating in a salt bath furnace, heating in a protective atmosphere (such as purified inert gas, controlling the carbon potential in the furnace), and flame combustion furnace (making the furnace gas reducing).

4.Hydrogen embrittlement

The phenomenon of reduced plasticity and toughness of high-strength steel when heated in a hydrogen-rich atmosphere is called hydrogen embrittlement. Hydrogen embrittlement can also be eliminated by dehydrogenation treatment (such as tempering, aging, etc.) of workpieces with hydrogen embrittlement. Heating in a vacuum, low-hydrogen atmosphere or inert atmosphere can avoid hydrogen embrittlement. When tempering is performed in time after quenching in a continuous heat treatment furnace, oxygen removal can be taken into account during the tempering process. According to current usage and statistics, products treated in continuous controlled atmosphere heat treatment furnaces generally do not experience hydrogen embrittlement.