Industrial continuous mesh belt powder metallurgy furnace sintering furnace line

This continuous gas shielded heat treatment furnace mainly use for powder metallurgy bright sintering and reduction. Such as , Machine Parts, Stainless Steel Powder,Iron Powder , Copper Powder . And Metallic Seal, Terminal Sintering, Sliver Sintering Heat Treatment, etc.

* The furnace boasts stylish design, rational structure, energy saving, high heat efficiency, stable production quality, safe and easy operation, not generating industrial pollution.

* Advanced temperature control : Intelligent thermostat, silicon controlled rectifier and schneider electrical switches ensure temperature control precision of ±1℃;

* The heating hearth (muffle)is made of imported Sweden high-temperature resistance nickel alloy (310S),Ensure that the workpiece after annealing to meet the process requirements;

* Heating elements: High-temp. resistance wire is used, with alumina tube frame; heating elements are arranged in an upper-lower removable to ease repair or replacing; replacing resistance wire has no impact on production;

* Steel belt conveying is stepless speed regulating.

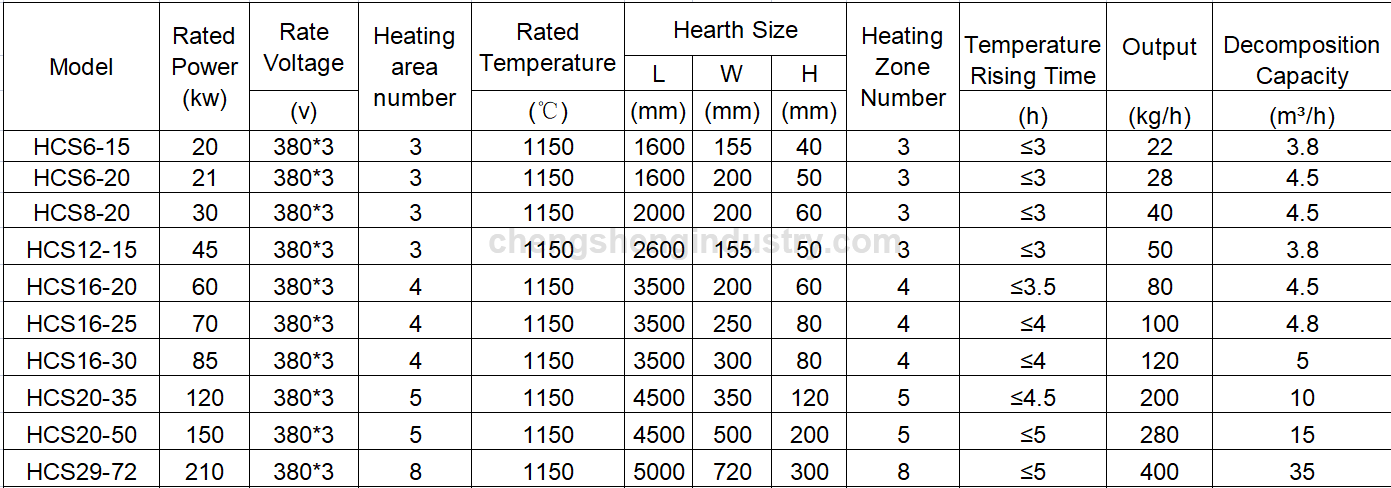

Tips:We have Professional R&D engineer, customized furnaces as your required is welcome.

Mainly use for powder metallurgy bright sintering, Machine Parts, Stainless Steel Powder, Metallic Seal, Terminal Sintering, Sliver Sintering Heat Treatment, etc.